Today, I'm going to remove the crank from this /2 bottom end. This is part of the R69S motor rebuild project. The Slash Two motor is a wonderful little engine. Slash Two engines are virtually indestructable and run very well, even on very little maintenance.

The main problem with this motor is the oiling system. In addition to a small gear oil pump, the crank bearings are oiled by centrifugal action. Oil slingers on the main crank shaft whirl the oil inside a centrifuge and it is then pumped through the crank shaft hollow center.

The centrifugal action causes the particles in the oil to separate and eventually harden inside the slinger. Once the slinger has filled up with particles, the oil hole is blocked and the crank bearings will no longer receive oil, leading to catastrophic results.

It is recommended that you tear down your Slash Two engine every 20k-40k miles to inspect and clean the slingers.

It is recommended that you tear down your Slash Two engine every 20k-40k miles to inspect and clean the slingers.

This is the process:

|

| Lock the flywheel and use a 41mm socket to remove the crank nut. |

|

| Note position of the locking washer. If it is all bent up, put this on your parts list to order a new one. |

|

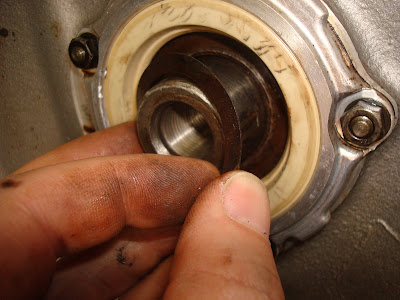

| Use a puller to remove the cage. This is a Bunch tool #216. I have a peice of aluminum between the center screw and the crank nose to protect the crank nose. |

|

| The slinger screws should be punched with a screwdriver or cold chisel when installed. Always use new screws when reassembling. |

The crank is removed! In the next episode, we'll remove the rear bearing and rear slinger.

Great pics and comments Scottie......even if it is a girl ;))

ReplyDeleteWhat a fantabulous post this has been. Never seen this kind of useful post. I am grateful to you and expect more number of posts like these. Thank you very much. Suzuki bikes price in Bangladesh

ReplyDeleteHow did you remove the rear bearing on the crankshaft? Looking at mine and wondering what to try?

ReplyDeleteThis blog is incredibly insightful! The content is well-researched and presented in an engaging manner. I appreciate the valuable information shared. Keep up the great work, and I look forward to reading more!

ReplyDeleteHalltronics

Enrgtech

Bearing Puller