Early blocks did not have RHS piston skirt oiling galley. This often leads to overheated RHS pistons and piston/cylinder scoring, and sometimes engine seizure. Scottie's can machine your block to include the oil galley, exactly like the later engine blocks. Machine shop time is about 3/4 hour. Call us for details.

Repairs, maintenance, and restorations of vintage BMW Motorcycles and Isetta/700 - Airhead and Gen 1 K-bike - Full Service Motorrader Machine Shop: Cylinder Head, Boring/Honing, Precision Grinding, Welding, Crankshaft Rebuilding, Engine and Gearbox repairs, Glasurit 22 and 55 Paint and Hand-Painted Stripes

Showing posts with label /2 Slinger Service. Show all posts

Showing posts with label /2 Slinger Service. Show all posts

Sunday, January 08, 2017

Wednesday, September 23, 2015

Make a Shipping Box for a /2 era motor

Scottie's Workshop has a wooden crate that we loan out to folks who want to ship their motors to us for work. We charge a deposit of $300 for the box that will be returned when the box is returned to us. If you want to ship your motor to us in the box, just give us a ring or email and we'll send it out to you.

Here's how you can build your own wooden crate.

Assemble top box as shown in photos below. Glue and clamp mating edges. Drill holes and use nuts and bolts to fasten angle brackets to strengthen joints. Affix heavy duty folding handles.

Optional: Affix corner braces inside and out to reinforce corners.

Assemble bottom as shown in photos below. Glue and screw bottom tier to bottom leaving 3/4" "shelf" around edge (to locate and secure the box lid). Glue and bolt feet and motor mount to base plate. Drill and locate the angle iron (or aluminum) to secure the motor. I ran long carriage bolts all the way through to the base and counter sunk the base of the bolts and fender washers.

The small piece of 2x4 you see jutting off to the side is just to secure a small cardboard box inside so it won't slide around.

Place the lid on the bottom plate (you may need to sand to fine tune the fit) and affix the butterfly latches, handles, etc.

** If you wish to secure the top of the engine (not really necessary, but I did it on ours), reduce the dimensions of the front and back and sides from 19" to approximately 18.125" and fabricate a steel plate to accept the top motor studs, as pictured below. Drill oversized 1" holes in top lid to access nuts. Affix plate to lid to locate top engine mount studs.

Test fit your motor!

Here's how you can build your own wooden crate.

- Front and back - Qty 2 - 19"** X 31.75" 3/4" Plywood

- L and R Sides - Qty 2 - 15.375" X 19"** 3/4" Plywood

- Top and Bottom - Qty 2 - 17" X 31.75" 3/4" Plywood

- Bottom Tier - Qty 1 - 15.5" X 30" 3/4" Plywood

- 1-1/2 in. x 14-Gauge x 72 in. Zinc-Plated Slotted Angle

- Sufficient nuts and bolts and washers

- Heavy Duty Handles

- Locking clasps - Such as surface mount ATA twist butterfly latch

- Corner braces - Such as Everbilt Model # 15442

- Feet - Qty 2 - Length 17" - pressure treated 4X4

- Engine mount - Qty 2 - Length 15" - pressure treated 4x4

- Angle iron - Length 9" - motor mount holes are 7 5/8" on center

- Length 9" - 3/8" all thread, nuts and washers

Assemble top box as shown in photos below. Glue and clamp mating edges. Drill holes and use nuts and bolts to fasten angle brackets to strengthen joints. Affix heavy duty folding handles.

Optional: Affix corner braces inside and out to reinforce corners.

Assemble bottom as shown in photos below. Glue and screw bottom tier to bottom leaving 3/4" "shelf" around edge (to locate and secure the box lid). Glue and bolt feet and motor mount to base plate. Drill and locate the angle iron (or aluminum) to secure the motor. I ran long carriage bolts all the way through to the base and counter sunk the base of the bolts and fender washers.

The small piece of 2x4 you see jutting off to the side is just to secure a small cardboard box inside so it won't slide around.

** If you wish to secure the top of the engine (not really necessary, but I did it on ours), reduce the dimensions of the front and back and sides from 19" to approximately 18.125" and fabricate a steel plate to accept the top motor studs, as pictured below. Drill oversized 1" holes in top lid to access nuts. Affix plate to lid to locate top engine mount studs.

Test fit your motor!

Monday, May 25, 2015

Friday, October 11, 2013

Media Blasting Aluminum Cases

When refurbishing a motor, or an entire bike, it is often desired to improve the cosmetic appearance of the cast aluminum cases. There are several cast aluminum parts on the bike that benefit from being media blasted and those include:

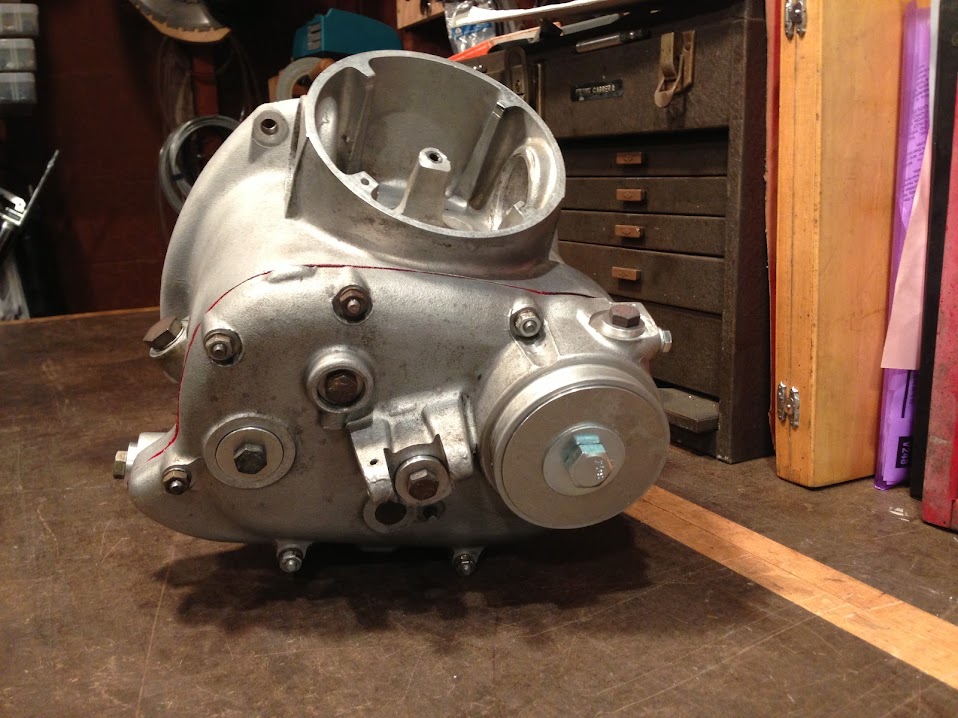

The following photo illustrates a freshly blasted transmission case next to a deep cleaned, natural patina engine block.

- Engine block, timing cover (intermediate case), electrics cover (front cover) and the semi-circular door on the top of the engine,

- Heads and valve covers,

- Transmission case and door,

- Wheel hubs.

Many owners blast the bottom of the rear shocks and then paint them or clear coat them. However I prefer to have them cadmium plated. When cadmium plating, I do not blast them; I just send them off and have the plater take care of it.

Scottie's workshop always media blasts cylinder heads when they are disassembled for refurbishing and machine work during a head service or repair. We also blast the valve covers so they come back to the customer matching the newly cleaned cylinder heads.

Because valve covers do not have any crevices, they can be media blasted without special consideration, so long as they are cleaned thoroughly after blasting to remove any residual media.

Wheel hubs can be blasted only during a wheel rebuilding service. Prior to building, the bearings and old spokes are removed and the braking surface is protected with masking tape. Then the wheel can be rebuilt. Once the wheel is spoked and trued, then the braking surface can be trued on a lathe.

Blasting Media

For ease of clean up and less wear on the case surfaces, I recommend using beads.

Blasting Media

For ease of clean up and less wear on the case surfaces, I recommend using beads.

Vapor Blasting

Vapor blasting (or vapor honing) is a blasting process in which the part is media blasted with glass beads and then blasted again with a fine slurry of very small glass beads and water/chemical cleaning agent solution. The resulting finish is stunning and far superior than blasting alone. In addition to the fine satin finish of aluminum parts, the aluminum retains a resistance to staining. At Scottie's Workshop, we only media blast parts that are to be powder coated or painted. We vapor blast everything else.

Engine and Transmission Cases

Before jumping into blasting your cases, you may want to give some thought to the end appearance of your bike after plating. For example, if you are rebuilding your transmission, and decide to blast it clean, consider how it will look when bolted back up to your motor, which may have its original patina.

When refurbishing and/or restoring a /2, we will normally media blast all the cast aluminum, or we will blast none of it, preferring instead to "deep clean" and preserve the original patina as best as possible. I discuss deep cleaning in another article.

The following photo illustrates a freshly blasted transmission case next to a deep cleaned, natural patina engine block.

|

| RTV and base gasket nuts (and some washers) are used to seal the poly to the case. |

|

| The transmission (studs removed) makes a handy template for tracing and cutting a door for the bell housing. RTV and nuts and washers are used to seal the poly to the case. |

|

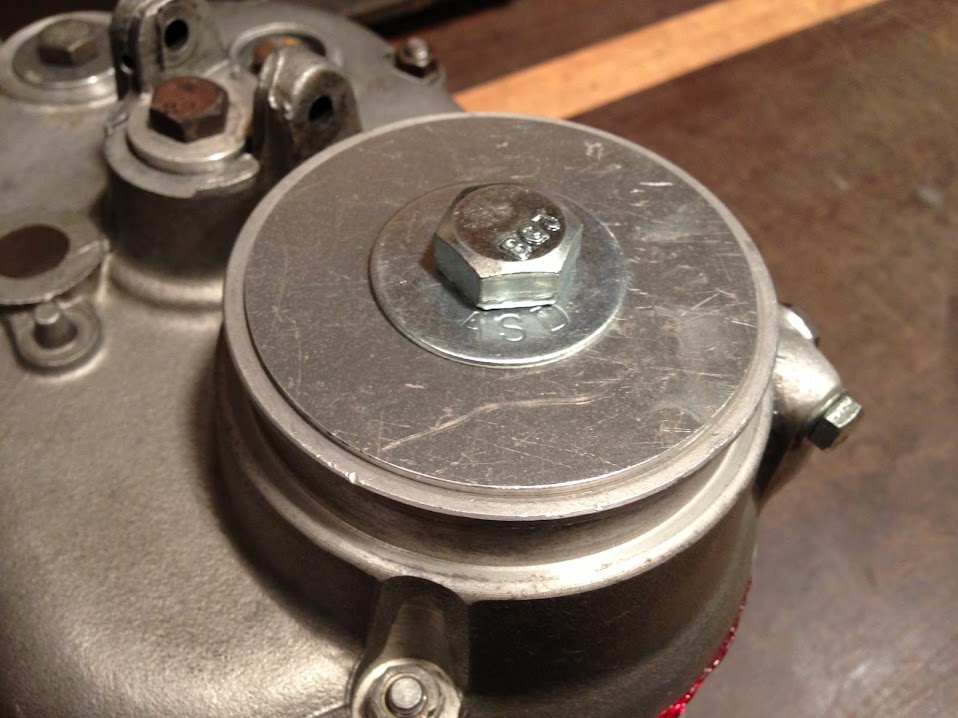

The semi-circular door on top is sealed with RTV and tightened down. Other holes are sealed with rubber bungs, or aluminum plugs made on the lathe, as shown in the photo below.

|

|

| On the transmission bench, my friend Blaise Descollonges has come up with a novel method to seal the many circular-shaped openings of the transmission case. |

| Bungs were cut on a lathe from aluminum. |

|

| The bungs have beveled edges so that they seal air tight. |

Tuesday, April 30, 2013

Monday, April 29, 2013

Subscribe to:

Comments (Atom)