If you are rebuilding, repainting, or restoring, it is highly advised to inspect the frame for bends. If you know (or suspect) that the bike was involved in a crash, or if the bike rides crooked (rides straight but the bars are cockeyed to one side), if it takes more effort to turn left vs. right (or vice versa), or if, when riding the bike down a straight and level road, the bike is leaned one way or the other in order to make it track straight, you must inspect the frame. Something is probably bent.

Now it could be your frame is bent. Or it could be the fork, or front or rear swingarm. Or the handlebars could be bent. This procedure only focuses on determining if the frame is bent.

This procedure is well documented in the Barrington manual, which is a highly recommended book for mechanics of vintage BMWs.

First obtain two straight tubes or rods. One must fit through the steering tube. A fork tube works nice for this. The other must fit through the rear swingarm pivots in the frame. I went to the local metal yard and picked up some stainless steel tube for this, but anything strong and straight will work well.

Next you'll need a carpenter's square, a C-clamp and a few bungie cords.

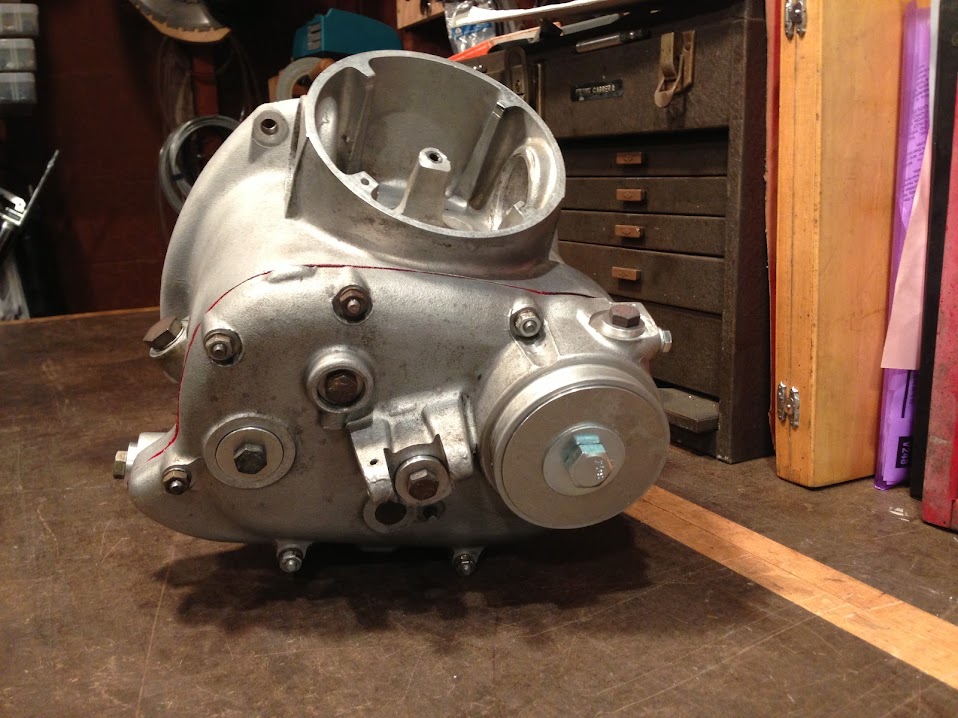

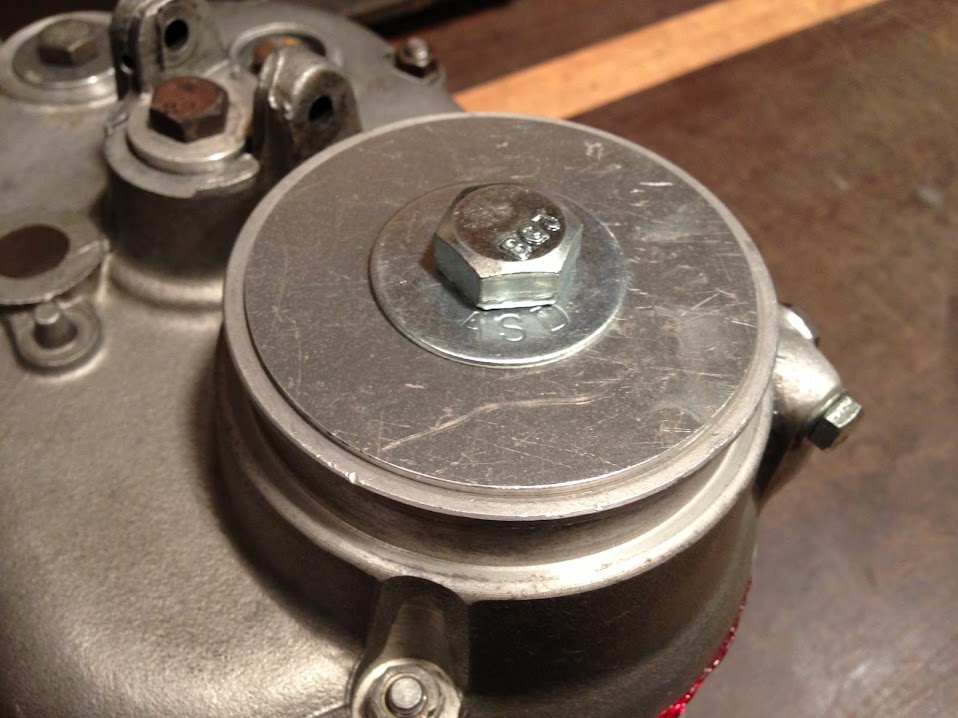

Arrange the smaller diameter rod through the rear swing arm pivots and bungie in place. You want to ensure that the rod is pulled in the same direction on both sides so that it sits square to the travel line of the bike. Bungie it in place. Now clamp the square to the rod so that you have a perpendicular reference. Arrange the square so that it is positioned in the "window" of the battery tray. See photo below. Click to enlarge photo.

What is important here is that the carpenter's square gives you a good perpendicular reference to the plane formed by the rear swingarm pivots, and also that you can see the reference in the window of the battery tray. (See photo below).

Now arrange your larger reference straight tube through the steering head and bungie it in place. Again you want to ensure that the tube sits square on the upper and lower bearing race lands in the same spot. I think it's easy to pull it back towards the back of the bike, and then bungee cord it in place. (See photo below.)

Now that you've done this, you can compare the two vertical lines formed by the carpenter's square and the tube going through the steering tube. If it is not exactly lined up, check your reference tube positions to be sure they are positioned correctly, and check your square to be sure it is settled in place.

If the frame appears to be bent, then you'll need to take the next step which is to take the frame to an alignment shop and have it measured with professional equipment, and straightened, if necessary.